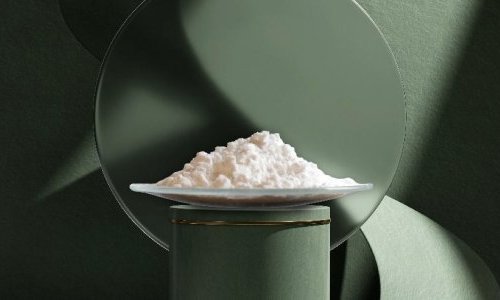

After decades of disuse, hygiene and care products in the form of powder are making a comeback. Now that solid products are widespread, this galenic form is booming. Products can be used as such or, increasingly, and extemporaneously, in formulas to be reconstituted. Several young Clean Beauty brands have already seized on the concept, highlighting the naturalness of the formulas and the benefits of reduced packaging.

Let’s take the example of Neo By Nature, which was launched last fall. The young brand has developed a shower gel to be reconstituted in a stainless steel pump bottle using compacted powder tablets. The organic-certified formula is composed of 99 % of ingredients of natural origin, and the sleek bottle is infinitely refillable.

“For us, the customer benefit is not ecoresponsibility: that is our mission! The benefit should be to have the best possible shower gel. To this aim, we use high-quality natural actives, including a biosaccharide with moisturizing and anti-ageing properties. It’s not a mere shower gel, it is a super shower gel”, says Hector Sentilhes, co-founder of the brand.

To achieve the level of efficacy and sensoriality required to compete with conventional liquid formulas, the two founders turned to the expertise of their partner, Fareva, an expert in cosmetics outsourcing. The collaboration resulted in 18 months of development and helped find the right balance in terms of formulas and manufacturing, despite specific constraints.

Formulation and industrialization challenges

Fareva has 42 production sites, including Le Laboratoire du Bain in France, a site originally dedicated to effervescent powders and bath pebbles.

“This business was slowing down because people no longer have baths regularly, but we wanted to showcase our expertise in powder manufacturing and compacting, with formulas that have real functionality. We work with direct-use powders and powders for dilution”, explains Antoine Dubrana, Marketing and Communication Director of the Fareva group.

For both solutions, the manufacturer uses his expertise to address identified issues specific to this type of product.

“It’s a completely different approach. We use a dry process, so the actives, the surfactants, and everything that makes the formula efficient must be in powder form. It considerably reduces the range of ingredients, which must also generally be of natural, or even organic origin. The same goes for perfumes, oils and colouring agents, which need to be worked on differently, because they are liquid ingredients”, says the expert.

“Compaction is complicated with formulas which are not completely dry: we had 1% of perfume added at the time of mixing”, adds Hector Sentilhes.

Another important criterion is the powder’s sufficient castability, which helps obtain free flow in the different canals, without sticky effects. “This is one of the most complex and technical points in powder formulation”, says Antoine Dubrana.

Powders compressed into tablets to be diluted by consumers involve additional challenges related to the use scenarios.

“We need to find the right balance to ensure the powder is well compacted, and dissolution is not too slow for users, since the dilution time is generally of 6 to 8 hours for large sizes, and 3 to 4 hours for pill sizes”, explains Antoine Dubrana.

The same remarks were made by Lessonia, an ingredient and cosmetics designer and manufacturer. Already specialized in powder masks to be reconstituted, the laboratory has equipped itself with an industrial tool adapted to powder production, packaging, and compression. It also offers a range of customized products to rehydrate, including shampoos, shower gels, micellar water, and shaving foam in the form of powder, granules and tablets.

“We use technologies that take into account powders’ rheology, particle size distribution, behaviour, and flow. Our know-how is based on our ability to mix them, screen them, make them fluid, and package them”, says Charles Henri Morice, Director of Innovation.

Granules, a new form to follow up

“Tablets to be rehydrated are getting increasingly popular, because the process is easier for consumers, but they need to dissolve easily, so it’s a real development challenge. Last year, we made an industrial investment to package powders in bottles. More recently, we purchased a tablet press machine, and we’ve been investing in a granulation machine”, adds Lessonia’s Innovation Director.

Granules, i.e. powders with a larger grain size, have several advantages, according to the specialist. “With granules, we can solve the issue of fine and volatile powders that might be inhaled. The flow is more fluid, packaging is easier, and the granules are more easily soluble and easier to work with, because there are fewer problems of particle mixture or segregation, which can change the initial composition”, he says.

An innovative form

Although the development of powders of any form is still mainly reserved for young independent brands, the approach has many advantages as regards ecodesign. According to a life cycle study conducted by Lessonia, powder shampoo saves half the water, energy, and greenhouse gas emissions of a liquid shampoo.

Available in three fragrances – sweet almond, lavender-rosemary-lemon, and bamboo-hemp – the Neo By Nature shower gel is currently distributed on the brand’s website, in 90 Nature & Découverte outlets in France, in some 15 pharmacies, and in several independent stores.

A recent fundraising of one million euros will help develop four new products. “They will be bathroom products to be diluted, with a strong focus on innovation. Two of them are concepts never seen before”, says Hector Sentilhes.

Fareva has announced a powder deodorant to be rehydrated in a refillable roll-on container for spring.

“Major brands have not really focused on this issue yet, because the ecosystem needs to develop, particularly in terms of ingredients providing naturalness and sensoriality. The concept also puts a lot of power in the hands of consumers: they are responsible for the dilution and proper cleaning of the container, and there can be a fear of misuse that backfires on the brand. The implementation of the French no-waste AGEC law, or of the cosmetic eco-score will most certainly accelerate the growth of this form”, concludes Antoine Dubrana.