Whether in cosmetics, in clothes, detergents and many products of our daily life, microplastics are everywhere. They even have been found in air, water, and soil as well as in the bloodstream of animals and people around the world.

While many manufacturers are looking for alternatives to these products, scientists from the Massachusetts Institute of Technology (MIT), in a joint work with BASF, have come up with an alternative that is surprisingly sourced from silkworms [1].

"The EU has already declared that these added, nonbiodegradable microplastics must be eliminated by 2025, so the search is on for suitable replacements, which do not currently exist," the researchers explain in a statement.

Silk fibroins

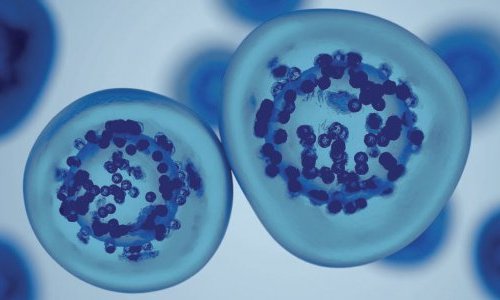

MIT researchers were interested in the properties of silk fibroins, which are not soluble in water while remaining biodegradable by the proteolytic enzymes commonly produced by living organisms.

Using spray drying and ultrasonic spray freeze drying processes, the team of engineers designed and fabricated silk-based microcapsules with a wide range of structures.

"By precisely adjusting the polymer chain arrangements of silk materials and addition of a surfactant, it is possible to fine-tune the properties of the resulting coatings once they dry out and harden," the scientists explain.

The material can thus be hydrophobic (water-repelling) even though it is made and processed in a water solution, or it can be hydrophilic (water-attracting), or anywhere in between, and for a given application it can be made to match the characteristics of the material it is being used to replace.

Recovering used silk fabric

Considered "safe" in the food and medical fields, silk is a biodegradable and non-toxic material for the body. It is also relatively easy to obtain as it can be extracted from the cocoons of silkworms or recovered from used silk fabric (or inferior-quality silk, unusable for textile manufacturing).

Currently, 90 percent of the world’s silk production takes place in China. However, that’s largely because the country has perfected the production of the high-quality silk threads needed for fabrics. The process developed by the MIT engineers uses bulk silk and has no need for a high level of quality. "Production could easily be ramped up in other parts of the world to meet local demand if this process becomes widely used," says MIT professor of civil and environmental engineering Benedetto Marelli, co-author of the research.

It is thus possible to carry out these encapsulations from cocoons of non-textile quality or even by recovering the silk of used fabrics. “The process is simple and can be implemented in existing factories,” says Muchun Liu, post-doctoral researcher at MIT and lead author of the study.

While other similar experiments have been conducted before with biodegradable materials to replace microplastics, the MIT team insists that encapsulating high-content active substances is necessary to pave the way for commercial use.

"The only way to have an impact is where we can not only replace a synthetic polymer with a biodegradable counterpart, but also achieve performance that is the same, if not better," explains Benedetto Marelli.

A small part of the plastics issue

Micro-plastics that are intentionally added to consumer products represent only a minor part of the global pollution linked to plastics (10 to 15% according to the European Chemical Agency); indeed, much of the burden comes from other sources, such as the degradation over time of larger plastic objects such as bottles and packaging, and from the wear of car tires.

“We cannot solve the whole microplastics problem with one solution that fits them all. Ten percent of a big number is still a big number,” highlights MIT professor of civil and environmental engineering Benedetto Marelli, co-author of the research.